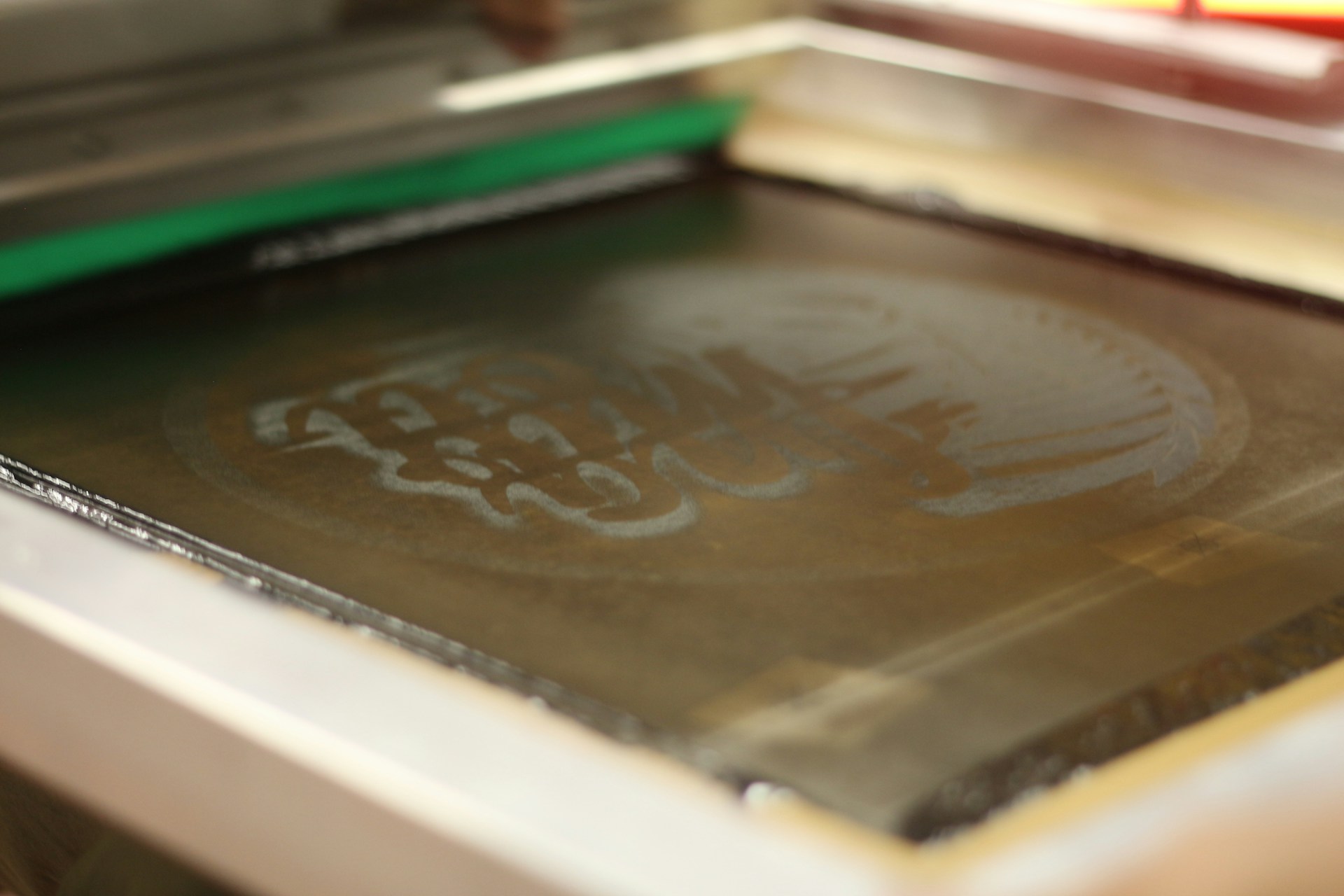

Screen printing is a remarkable craft that requires careful attention and dedication. Maintaining the equipment involved in screen printing not only ensures its longevity but also improves the quality of every print produced. In Fort Myers, where creativity and craftsmanship come alive through vibrant prints, taking the right steps in maintenance can make all the difference. Whether you're working on designs for local businesses or personal projects, keeping your screen printing equipment in top condition is key to producing outstanding results.

Proper maintenance of screen printing equipment involves regular cleaning, careful storage, and addressing wear and tear. These practices help prevent costly breakdowns and keep everything running smoothly. For those engaged in screen printing in Fort Myers, understanding how to take care of your tools can lead to consistently high-quality prints that meet the needs of clients and personal creative goals alike.

Regular Cleaning and Inspection

Routine cleaning and inspection are essential for effective screen printing equipment maintenance. Dust, ink, and debris can build up over time, leading to jams and imperfect prints. Regular checks prevent these issues and ensure that your equipment functions optimally every day.

Here's how you can keep your equipment clean and running smoothly:

- Daily cleaning: Make it a habit to clean screens, squeegees, and platens at the end of each day. Wipe down surfaces to remove any ink residue or dust particles. This quick routine helps in maintaining clean prints.

- Weekly inspections: Allocate time each week to inspect moving parts and check for signs of wear or damage. Look for clogged nozzles or mechanical parts that might need attention.

- Focus on different parts: Use mild cleaning solutions specifically designed for screen printing. Pay attention to frames, screens, and press components. Regular care prevents contaminants from affecting the final prints.

By keeping a consistent schedule for cleaning and inspection, you can easily spot problems before they escalate. This proactive approach preserves the integrity of your designs and ensures every print meets your standards.

Proper Storage Solutions

Storing screen printing equipment correctly is just as crucial as cleaning it. Proper storage prevents damage and extends the lifespan of your materials. In Fort Myers, with its humid climate, understanding how to store everything properly can protect your investment.

Taking smart steps in organizing and maintaining your storage space makes your work areas more efficient:

- Store screens flat: Always store screens flat in a dry area. This avoids warping and maintains the mesh tension, which is crucial for precise printing.

- Organize by item type: Designate specific spaces for different equipment pieces. Keep inks, chemicals, and coating materials in controlled environments to prevent degradation.

- Label everything: Use tags or labels to identify the contents of boxes and shelves. This not only speeds up your workflow but also keeps your inventory in check.

With these storage methods, your screen printing equipment will be ready for action whenever inspiration strikes, ensuring reliability and quality in every print.

Lubrication and Calibration

Keeping screen printing equipment well-lubricated is crucial for smooth operation. Lubrication ensures that moving parts glide effortlessly, which helps avoid unnecessary wear and tear. When equipment operates smoothly, the likelihood of mechanical failures diminishes, leading to more consistent print quality.

Here’s how you can keep your equipment running like new:

- Regular lubrication: Apply lubricant to all moving parts according to the manufacturer's recommendations. Pay extra attention to critical areas like hinges, which can easily become stiff if not maintained regularly.

- Calibration checks: Regularly check equipment calibration to maintain print accuracy. Incorrect settings can lead to blurred or uneven prints, which may affect the overall quality of your work.

- Monitor for noise: If you hear unusual noises during operation, it could be a sign that parts need lubrication. Address these signs early to prevent larger mechanical issues.

By incorporating lubrication and calibration into your routine, you'll extend your equipment's life and ensure every print meets your expectations.

Addressing Common Wear and Tear

Screen printing equipment faces inevitable wear and tear, just like any tool that's used regularly. Recognizing these signs early allows timely repairs or replacements, ensuring your projects proceed without hitch.

Common signs to look for include:

- Worn squeegees: Squeegees can wear down with constant use, leading to poor ink distribution. Check edges for smoothness, and replace them when they show signs of aging.

- Damaged screens: Regularly inspect screens for tears or damage. Even small nicks can result in incomplete prints, affecting consistency and detail.

- Belt and roller wear: Observe belts and rollers for slippages or signs of excessive wear, which may lead to unexpected breakdowns.

When faced with wear that you can't fix on your own, consider seeking professional help. Knowing when to hand over the tools is a vital part of maintaining your equipment efficiently.

Seasonal Maintenance Tips

Fort Myers weather can be tricky for screen printing equipment, especially during high humidity or dry periods. Adapting your maintenance based on the season helps protect your tools from environmental stress.

Here are some tailored tips:

- For humid conditions: Use dehumidifiers in storage areas to prevent moisture buildup, which can lead to equipment rusting. Consider using fans to keep air circulating.

- During dry seasons: Increase lubrication frequency as dry air may cause faster evaporation, affecting equipment movement. Store sensitive materials in airtight containers.

- Seasonal storage: Adjust storage practices to prevent degradation due to seasonal changes. For example, cover equipment with tarps during humid months to prevent rust.

Anticipating how weather affects your equipment helps you prepare adequately, ensuring that your screen printing setup stays in peak condition all year long.

Ensuring Consistent Quality

Consistent maintenance is directly linked to print quality. Implementing effective care routines not only extends equipment life but also ensures superior print results. Keeping your screen printing outputs consistent leads to satisfied clients and successful projects. Maintaining a log to track equipment performance can help in swiftly identifying any discrepancies and addressing them promptly.

Keeping Your Equipment Future-Ready

In the fast-paced world of screen printing, it's crucial to adapt maintenance practices for new technologies. Keeping abreast of the latest techniques ensures your equipment's longevity and reliability. Building a routine that embraces both new advancements and traditional methods enhances your equipment's capabilities.

Top Maintenance Resources for Fort Myers

To support your maintenance efforts, connecting with local Fort Myers resources can be invaluable. Seek out professional services, engage with the screen printing community for advice and tips, and explore local suppliers and workshops dedicated to screen printing care.

Maximizing Screen Printing Quality in Fort Myers Through Equipment Care

Caring for your screen printing equipment is a continuous process that pays dividends in quality and reliability. By sticking to a rigorous maintenance routine, you ensure that every print reveals the vibrant creativity that Fort Myers is known for. From regular cleaning to adjustments during weather changes, each step paves your path to consistent success.

Understanding and implementing these tips will transform your equipment into a dependable ally in your creative projects. With a bit of effort and attention, your screen printing tools will last longer and perform better, all while producing prints that capture the essence of your vision. By prioritizing maintenance, you're setting up your workshop for continued excellence and creativity for many years to come.

Elevate the quality and longevity of your screen printing projects with expert care and maintenance tailored for every season. At iCON Advertising, we specialize in screen printing in Fort Myers that help your equipment deliver exceptional results time and again. Embrace practices that keep your machines operating smoothly, ensuring your prints are always vibrant and precise. Explore our resources and let us support your creative journey with unmatched expertise.