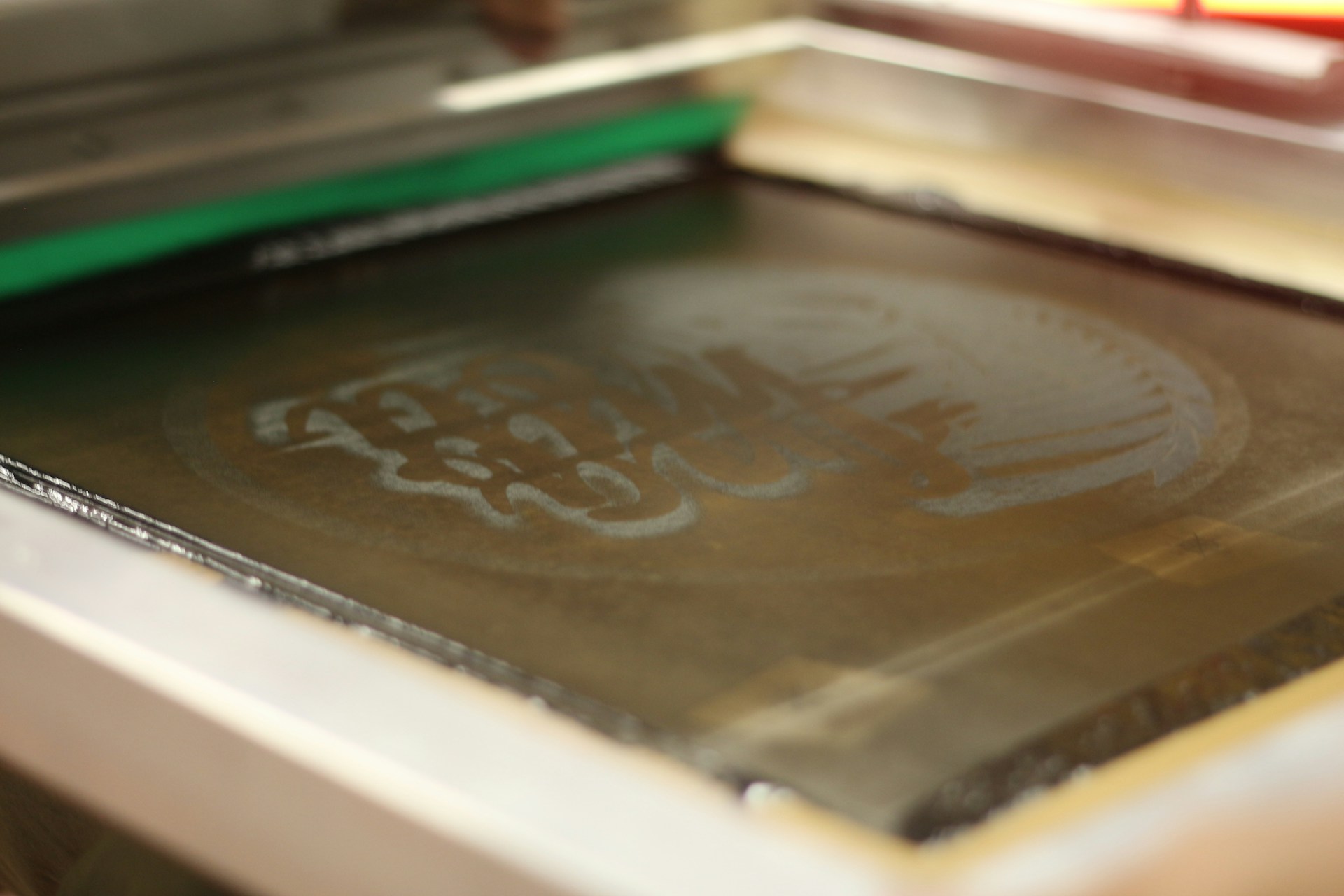

Screen printing has become a popular choice for custom designs on various materials, from T-shirts to posters. It's a versatile process embraced by businesses and individuals in Cape Coral for its brilliant colors and durability. However, achieving flawless prints requires attention to detail, especially when it comes to registration. This aspect is crucial to ensure that all colors align perfectly, creating a sharp and professional appearance. In Cape Coral, where vibrant designs are a staple, screen printing enthusiasts and businesses often encounter the challenge of poor registration. This issue can lead to designs appearing blurry or misaligned, compromising the overall quality of the print. Addressing poor registration effectively can enhance the visual appeal of your products and maintain a consistent quality standard. Registration in screen printing refers to the alignment of different color layers in a multi-color design. When registration goes wrong, you might notice misaligned colors or edges that don't meet perfectly. Poor registration can be noticeable, making the print look unprofessional and unfinished. Recognizing these signs early is the first step to correcting the issue. Poor registration impacts the final product significantly. It not only affects the aesthetics but also reduces the perceived value of the item. When offering screen-printed products, presenting high-quality prints is essential for maintaining customer satisfaction and building trust with clients. - Misalignment Issues: One of the most frequent causes of registration problems is the misalignment of the printing screens. If screens are not properly lined up, the colors will not overlap as intended. - Incorrect Screen Tension: The tension of the screen also plays a critical role. If the screen is too loose or too tight, it can warp or shift during printing, leading to misalignment. - Poor Quality of Screens: Using screens that are worn out or made of low-quality materials can also lead to registration issues. A substandard screen can shift unexpectedly, causing colors not to line up correctly. - Inconsistent Ink Application: Uneven application of ink or variation in ink viscosity can cause colors to bleed or not print evenly. This inconsistency contributes to inadequately registered prints. Understanding these common causes is key to diagnosing and fixing registration issues efficiently. Knowing what to look for allows you to take corrective action quickly and effectively. Correcting these problems not only improves the quality of the prints but also enhances the reputation of screen printing services in Cape Coral. Fixing poor registration in screen printing is all about paying close attention to detail and following some key steps to ensure perfect alignment. It's like building a house; you’ll want to start with a strong foundation and work your way up methodically. 1. Proper Screen Preparation and Setup: Begin by ensuring your screens are precisely prepared. This means lining them up accurately on the press and checking that the frames are sturdy and secure. 2. Ensuring Correct Screen Tension: Make sure the screens are stretched to the right tension. A loose screen can shift during printing while one that's too tight might stretch, both causing misalignment. 3. Calibrating the Printing Press Accurately: Regularly check the calibration of your printing press. An accurately set press ensures that each layer of color prints exactly where it's supposed to. 4. Regular Maintenance of Equipment: Keep your equipment in top shape. Cleaning and checking for any wear and tear will prevent unexpected shifts during printing. Making these techniques part of your process can greatly reduce the chances of poor registration. Think of them as regular practices that help maintain quality and consistency in your screen prints. Once your projects are back on track, it's vital to implement strategies that prevent issues from cropping up again. A bit of planning goes a long way. - Routine Checks and Maintenance Schedules: Develop a regular routine for checking and maintaining all equipment. Catching potential problems early can prevent them from becoming bigger issues. - Staff Training for Precise Techniques: Ensure everyone involved in the process understands how to achieve proper registration. Training your team helps maintain high standards. - Investing in Quality Materials and Equipment: Using top-notch materials and reliable equipment is a solid way to prevent registration mishaps. It might cost more upfront, but it saves time and money in the long run. Consistency is key to sustaining quality in screen printing. By putting these measures in place, you can significantly reduce the risk of encountering registration problems in future prints. Solving registration issues can greatly improve the outcome of your screen printing projects, enhancing both the look and feel of the products. Understanding what causes poor registration and how to fix and prevent it ensures that your efforts result in the quality prints you envision. Taking these steps not only saves time and resources but also helps deliver the high-quality products that Cape Coral customers expect. Having a proactive approach means fewer headaches and more success in delivering exceptional screen printing results. Embracing these practices means your screen printing business can thrive, offering vibrant and precisely aligned prints that make an impact. Boost your screen printing success by adopting these strategies that address and prevent poor registration. If you're eager to take your projects to the next level, explore how professional support can make a difference with screen printing in Cape Coral. Discover how iCON Advertising can help you achieve the vibrant results that your business deserves.Understanding Poor Registration in Screen Printing

Common Causes of Poor Registration

Techniques to Correct Poor Registration

Preventative Measures for Future Prints

Bringing Your Screen Printing Projects Back on Track

How to Correct Poor Registration in Screen Printing for Cape Coral